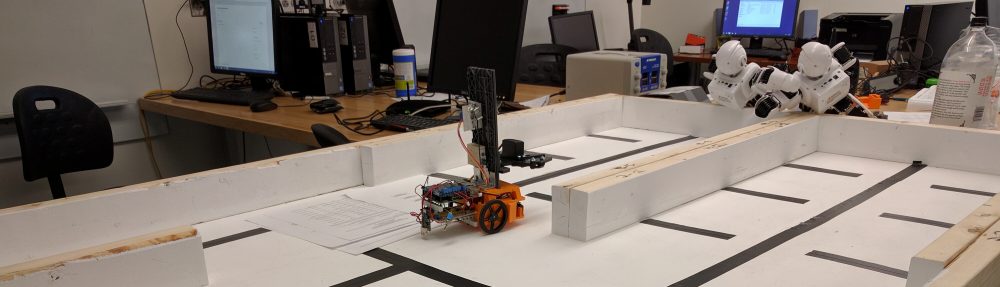

The project my team and I worked on was the automated warehouse project. The goal of the project is to have three robots that each can receive a package, scan the package, interpret its ship out date, and place that package in the appropriate location of the warehouse according to the warehouse’s specifications. All information related to the project itself is located on the project’s site here. The three videos in the footer are related to things I did specifically for the project.

For my part of the design team I helped in a few different ways. I have spent many hours in a wood shop and know how and have been certified before on all of the machines we have here at the University of Scranton. I, therefore, took the lead in building the mock warehouse floor itself. Once that was built and in room 142 the team was able to start running trials of the algorithm. The next major role I played was working on the design of the master, slave relationship the Fit PC3 and the Raspberry Pi’s were going to have. Using Windows 10 and FileZilla the system would connect to multiple Pi’s (as many as are needed, in the final prototypes case one) and send the required warehouse admin file with all pertinent data, including but not limited to storage locations, bot assignments, specific modified code, etc. This system was not able to be implemented with the project just yet. Time ran out for our team to set it up and fully realize it. I also had a hand in building the last two robots that were never finished because of lack of materials and a few other things in the project.