Hi! This is our database format for pulling the optimal growth conditions of a selected plant into the system for monitoring and adaption.

ECE454 Senior Design Project

Hi! This is our database format for pulling the optimal growth conditions of a selected plant into the system for monitoring and adaption.

Hi! This is the basic format of how the adaption algorithms for each controllable

variable will operate. In the case of this chart, we use pH as the example.

The Idea

Environmental factors play a sizable role in the life cycle of plants. These factors have the potential to impede large regions of food production and have a negative effect on our ability to readily, and affordably obtain plant based food. To provide a solution that circumvents these problems a multidisciplinary team of engineering and biology students are developing a self-contained, autonomous, and adaptive system for sustainable plant growth.

To accomplish this goal, research is being conducted on plant nutrition intake and how environmental factors dictate the growth cycle of plants in a variety of global regions. The data pulled from this research is being compiled into a database that provides expected growth conditions for analysis versus real-time measured variables. This analysis is the basis for adaption algorithms that modify the environmental conditions of the system and delivery of nutrient rich fog. The technology will serve to accommodate increasing demands on plant based food production that is independent of natural and uncontrollable factors using controllable and sustainable methods.

Introduction

Sustainable food production is a necessity to continued life on Earth. A problem with current food production technologies is the availability of arable land as population increases. Over a third of the planet’s habitable land is being used for food production (“Crop production and natural resource use”). This food production also accounts for 86% of Earth’s water usage (“Human Appropriation of the World’s Fresh Water Supply”). This land is being saturated with fertilizers and pesticides to produce the maximum amount of food in a minimum amount of time and space. Past methods of keeping land arable for longer periods of time by cycling patches of land and allowing for decaying matter to replenish soil are being forgone in order to keep up with a highly demanding need for fast production. This is leading to a depletion of soil and its nutrient concentration (Yang, “Human security at risk as depletion of soil accelerates, scientists warn.”). Without soil, there is no longer a vessel for plant growth, or a means for delivering nutrition to roots.

To circumvent this problem, a potential solution is to replace traditional farming techniques with technological methods for sustained food production. One such method is the use of automated and adaptive environments. Controlled environments allow for the elimination of many determining factors in a plant’s successful life cycle. These factors include pests, disease, season, weather and climate. The elimination of these factors can increase a crop’s impact increasing yield.

Many methods that bridge technology with food production are laborious, expensive to implement, difficult to upkeep, prone to failure, and most importantly, limited. The problem being, technology hasn’t been implemented enough for these environments to surpass traditional food production. They are limited to a certain subset of growth variables that are autonomously monitored and maintained through manual input of general settings.

This paper will discuss how an autonomous and adaptive environment is being developed to circumvent the need for human monitoring and adjustment through the use of an indoor growing environment that autonomously adjusts itself based on a database of optimal growing conditions fed into adaption algorithms.

Proposed Method

The perfect system for growing food is one that sets the optimal parameters for growth for a specific plant. This system is a closed environment that does not waste surplus or extraneous resources. Automation controls the growth factors and only allows for ideal conditions to exist. Soil in not required for plant growth, instead, plants are suspended above a nutrient rich water delivery system. If a problem arises, the system will adapt to the variance by adjusting growth parameters until the problem is corrected.

Database of Growth Variables

For a system to be adaptive it has to know how it’s expected to operate. In the case of plant growth, an adaptive system must have available basic variables for a plant’s growth cycle. The underlying requirements for growth are simple; water, nutrients, light, temperature, and oxygen and carbon dioxide, all of which vary from plant to plant, even if just slightly (“Requirements for Plant Growth.”). For a system to deliver these requirements adequately it must utilize a database of expected variables for a given plant. In the case of this system, the requirements for a range of different plants are needed, as to not limit itself.

The database will be composed of a selection of individual plants with their respective optimal growing requirements. These requirements are provided so that the system is independent of outside environmental factors such as region, climate, and season. The importance of varying these requirements to the given plant is described in the following sections.

Water

Water is the quintessential aspect of life. It is used to transport molecules around a living organism (“Why is water important for life?”). It seems simple; water your plant, and it will grow, however, plants absorb water at different rates and at different quantities during stages of its life cycle. Water quality is also an important factor. Alkalinity and salinity of water in these systems vary greatly, and could disrupt balance and reduce the quality of nutrient solutions (“Requirements for Plant Growth.”).

Nutrients

Nutrients are the elements required for proper cell growth and function. There are seventeen elements required for perfect plant growth, fourteen of which are delivered to the plant’s roots. A plant’s primary nutrients, nitrogen, phosphorus, and potassium and secondary nutrients, calcium, magnesium, and sulfur are delivered in large quantities. Smaller quantities of iron, zinc, molybdenum, manganese, boron, copper, cobalt, and chlorine are also required. The combinations of these nutrients vary greatly among plants, as their needs are all different (Whiting, “Plant Nutrition.”). Typically these nutrients are found in soils and absorbed as ion sludge through the roots as required. In water delivery systems, nutrients need to be added in precise proportions to not underdeliver or produce waste.

Light

Light is a plant’s source of energy, like food is ours. Visible light contains wavelengths from 400 to 700 nanometers. Plants typically absorb more blues and reds than greens and yellows. This has to do with the photosynthesis process. Chlorophyll absorbs blue and red light while reflecting green light, inducing photosynthesis in the leaves of plants to produce chemical energy. This energy carries out basic cell functions of plant growth.

Light also plays a critical role in a plant’s flowering response, known as the photoperiod. In outdoor environments, we have light time, and dark time. Plants require different ratios of these on off cycles for the flowering stages of development (Whiting, “Plant Growth Factors: Light”). In a controlled system, light must be varied by intensity, electromagnetic spectrum, light and dark times, and be evenly distributed to prevent phototropism and create a uniform growing environment. Phototropism is the tendency of a plant to grow toward an intense light source. To prevent this in an autonomous growing system, the light administered to the plant must be specific n direction and not just wavelength.

Temperature

It is known that plants grow better, if at all, in certain regions and seasons. Temperature has a large role in determining acceptable plant growth. Respiration and photosynthesis rates rise with increasing temperature, increasing higher crop yield, however, each plant also has a peak production value that if exceeded, reduces crop yield (Whiting, “Plant Growth Factors: Light”). Also, the higher the respiration rate, the less sugar produced by the plant, yielding more bitter crop and increasing demand for water.

Temperature also affects the production and development of pollen. Blossoms and flowers close and open at the proper temperatures. Deviating from these temperatures reduces flower quality and lifespan (Whiting, “Plant Growth Factors: Light”).

Oxygen and Carbon Dioxide

It’s common to believe that plants only require carbon dioxide due to the understanding that plants absorb it and produce oxygen as a byproduct of photosynthesis. This is true; however, plants also require oxygen for nutrient absorption. Oxygen transports nutrients into the cell wall surrounding roots through osmosis. In water delivery systems, the plants can be starved of nutrition despite having the proper solution if not adequately oxygenated (“How Oxygen Affects Plant Growth.”).

Plants also require carbon for growth, the source being carbon dioxide in air. Plants use carbon and water to produce sugar and oxygen. The sugar is used as a food source for the plant, where the oxygen is released into the atmosphere as waste. Under ideal conditions, increasing the carbon dioxide availability increases a plant’s ability to produce higher yields of crop (“Rate of photosynthesis: limiting factors.”).

Nutrient Delivery System

As discussed in sections 3.1.1, 3.1.2, and 3.1.5, the required nutrients for a given plant vary as do the conditions in which they are delivered. Indoor growing environments typically utilize water based delivery systems such as hydroponics and aeroponics. Both methods involve either submerging or spraying roots with a nutrient water solution. These methods produce waste in having to expose roots to large quantities of water and nutrients that regularly need flushing with new water to prevent acidity imbalance, stagnant water, and mold and algae growth (Dr. Morgan, “Article 5-4 Q’s Nutrient Problems.”).

Another form of aeroponics is fogponics. Fogponics utilizes ultrasonic transducers resonating at high frequencies to vaporize water. The water molecules produced this way are approximately five microns in size. Roots of plants typically absorb particles in the range of five to 15 microns, making this system ideal for nutrient delivery (Manali, “How Does an Ultrasonic Fogger Work?”). Because fog molecules are carrying particles on the lower end of a root’s absorption ability, the roots are exposed to a greater surface area of absorbable nutrient solution, theoretically increasing the rate of growth.

Monitored Environment

For a system to be autonomous and adapting, it must be capable of quantifying real-time data. To do so, sensors are used to record measurable variables of an environment. In the case of this system, clusters of basic sensors such as temperature, light intensity, and humidity measure data at different points. More advanced sensors analyze the spectrum of visible light, air toxicity, nutrient concentrations, water pH levels, and fog density.

A more complex method for analyzing plant growth and health is through image processing. Cameras can be used to measure visible plant health throughout its growth cycle. Color, orientation, and size are all factors considered in this type of analysis.

Controlled Environment

Controlling an environment uses measured data gathered from monitoring sensors and comparing it to expected results. This is where the database of expected growth variables becomes essential to the system. As measured data deviates from expected conditions, the system autonomously adapts itself to compensate for the changes. Using microcontrollers and other programmable circuitry allows for the system to adapt by adjusting hardware such as lighting fixtures, dispensers, heating elements, cooling fans, and ventilation.

Developing Technology

The autonomous and adaptive environment for food production is comprised of four major components: the fogger for nutrient delivery, sensors for monitoring growth variables, various electronic hardware for environment control, and adaption algorithms.

Fogger

Ultrasonic foggers transform electrical energy into mechanical energy through the use of a piezoelectric transducer. It does this by converting an electrical frequency between 1-12 MHz to a mechanical vibration of a thin membrane. The fogger is placed in a shallow pool of water that rises slightly above the membrane. As the membrane compresses and decompresses water in the area above it, capillary waves are generated and small particles of fog are released from the peaks (“Operating principle of ultrasonic humidifier.”).

Nutrients are added to the water creating a solution optimal for plant growth. As the membrane throws off small particles of water, nutrients around the size of five microns are carried with them. The nutrient rich fog serves multiple purposes. Because of its tiny size, the water droplets, or fog, stay suspended in air for longer periods of time than sprayed water. This gives roots an increased time in which to absorb nutrients from the solution, while simultaneously being exposed to large quantities of water and oxygen.

The foggers are placed in a chamber located below the root chamber, connected by a series of vertical tunnels. The fog chamber has a small pocket of air above the solution that is constantly pushed up through the tunnels by controlled air flow. The purpose for isolating the fog chamber from the root chamber is to use the minimum amount of solution required to generate fog and transport nutrients. This reduces waste from solution that is never fully used before it is flushed from the system.

Sensors

There are a wide range of sensors used in this system. Within the growth chamber, temperature, light intensity, oxygen, carbon dioxide, and humidity sensor clusters are placed at various points. These ensure the growing environment is constantly monitored. Also in the growth chamber are cameras and spectrometers. The cameras analyze visual aspects such as color, size, orientation, and budding/flowering. The spectrometers measure the emitted wavelengths of light from all sources and reflected light from the plant leaves and growth chamber surfaces.

The root chamber contains waterproof temperature sensors to ensure the chamber does not overheat and lasers for measuring fog density. Below, in the fog chamber, there are temperature, pH, and TDS (total dissolved solids) sensors for measuring solution quality.

Electronic Hardware

There are two primary controllers; a Raspberry Pi Computer, and a Mojo V3 FPGA. The Raspberry Pi Computer is a small Linux based CPU with microcontrolling capabilities. The Mojo V3 FPGA is a Spartan-6 device capable of fast I/O interfacing and added ATMEGA microcontroller for Analog inputs. The Raspberry Pi is attached to the Mojo V3 through the inter-integrated circuit (I2C) protocol, allowing for addressable two-way communication between multiple devices. The combination of controllers perform precise execution of instructions for hardware manipulation.

The grow chamber uses LED lighting arrays composed of numerous addressable RGB LEDs for altering the output light spectrum and intensity. Cooling fans are positioned in the root chamber as well as the grow chamber and are speed controlled through pulse-width modulation. The grow chamber fans also act as ventilators to cycle in and out air if oxygen or carbon dioxide levels exceed expected conditions. Solenoid valves are located throughout the environment to dispense nutrients into incoming water and to flush out used solution. Humidifiers, dehumidifiers, and heating elements are located in the grow chamber for maintaining optimal growing conditions.

Algorithms

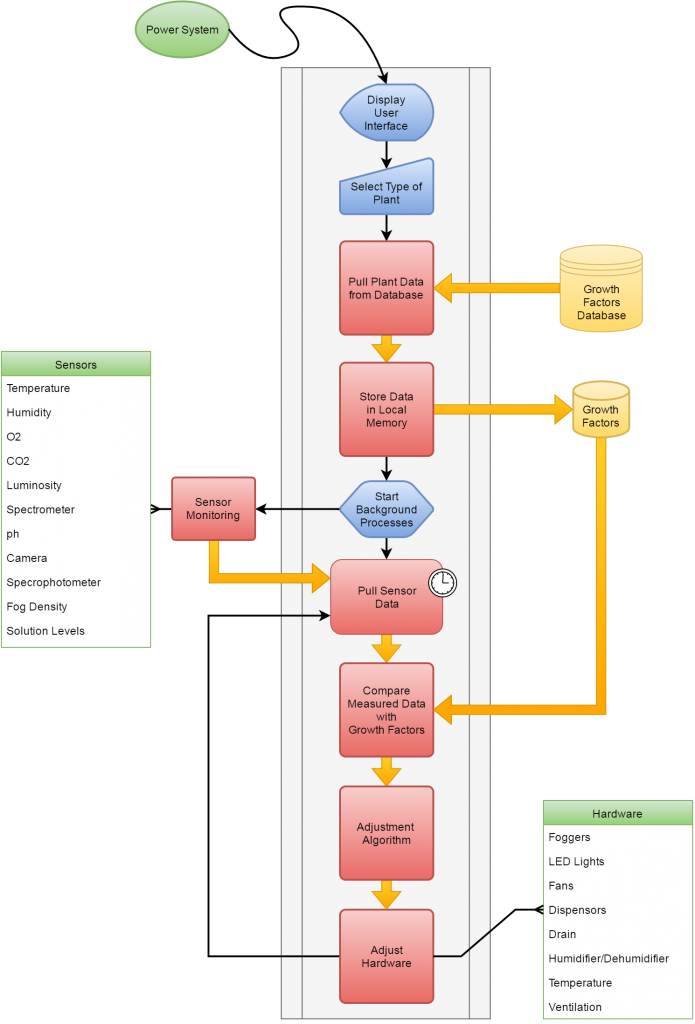

What brings the entire system together are the adaption algorithms. They are the bridge between monitoring and control. The monitoring system constantly updates fields of variables on a server hosted by the Raspberry Pi. Intermediate programs pull expected growth conditions from the database and compare them in real time to the updated fields on the server. If a discrepancy is detected, the intermediate programs kick off the corresponding control algorithm for that discrepancy. These control algorithms are different for each growth condition and piece of hardware, but similar in logical flow.

For example, a pH sensor is constantly polling the pH level of the currently used batch of solution. If at any point the readings vary from the acceptable database values, the algorithm will kick off a series of checks. The first check takes a number of samples over a set duration. If these samples remain within an acceptable tolerance, the system will continue normal operation and end the checks sequence. If, however, the pH level continues to deviate from the acceptable values, the system will compare the rate at which it approaches a critical point where damage to the plant may occur with the time until the next solution flush and change. If at this point the analyzed data is acceptable, it will continue to monitor the pH levels, but with lower processor priority. If, however, the analyzed data is not acceptable, the system will make an attempt to rectify the problem by balancing the pH level by injecting acidic, basic, or distilled water into the solution depending on the direction of variance and nutrient parts per million (PPM). Finally, if the measured values are beyond a critical point, the current solution will be flushed out and replaced with fresh solution.

The draft flow for the Foginator has been established. This is a flow chart of how the system will operate from start to finish. Of course, there are some key elements not included in the chart for simplicity’s sake. The purpose of the chart is to simply establish an underlining base of operation.

© 2026 Foginator

Theme by Anders Noren — Up ↑